|

|

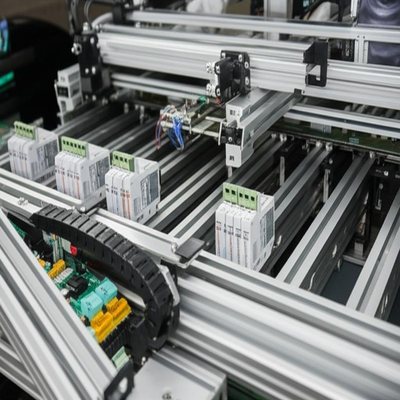

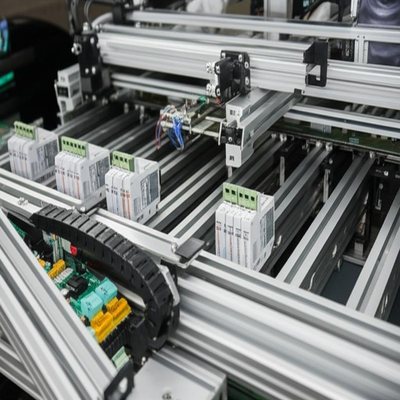

Schneider Relay and Meanwell Driver Circuit Board Handling Machinery for Smooth Production

Product Details: |

| Pcb Direction: | L-R Or R-L(optional) | Height Adjustment: | Feet Cup |

|---|---|---|---|

| Communication: | SMEMA | Air Pressure: | 4-6kg/cm2 |

| Relay Brand: | Schneider | Power Supply: | AC 110V/220V, 50/60Hz |

| Pcb Flow Direction: | L-R Or R-L (optional) | Driver Brand: | Meanwell |

| Highlight: | Schneider relay PCB handling machinery,Meanwell driver circuit board equipment,PCB handling machinery for smooth production |

||

Product Description:

Introducing our top-of-the-line PCB Handling Equipment, designed to enhance efficiency and precision in handling delicate Printed Circuit Boards (PCBs). This advanced machinery is a must-have for any electronics manufacturing facility, providing a safe and reliable solution for ESD Safe PCB Handling Tools.

With a versatile power supply capability of AC 110V/220V, 50/60Hz, our PCB Handling Equipment is compatible with various power sources, ensuring seamless integration into your existing setup. The equipment operates at an optimal air pressure range of 4-6kg/cm2, delivering the necessary force for precise and controlled handling of PCBs.

One of the standout features of our PCB Handling Equipment is its flexibility in PCB direction, offering the choice between L-R or R-L orientation (optional). This customizable option allows you to adapt the equipment to suit your specific production requirements, ensuring maximum efficiency and productivity.

Height adjustment is made easy with the innovative Feet Cup design of our PCB Handling Equipment. This feature enables you to quickly and accurately adjust the height of the equipment to accommodate different PCB sizes and configurations, providing a secure and stable platform for handling operations.

Equipped with high-quality Meanwell drivers, our PCB Handling Equipment delivers reliable performance and precise control over the handling process. The renowned brand ensures durability and efficiency, making our equipment a dependable and long-lasting investment for your facility.

Whether you are handling small-scale PCBs or large circuit boards, our PCB Handling Machinery offers the versatility and reliability you need to streamline your production processes. The equipment is designed to meet the demanding requirements of modern electronics manufacturing, providing a safe and efficient solution for handling delicate PCBs.

Features:

- Product Name: PCB Handling Equipment

- Sensor: Sick

- Relay Brand: Schneider

- Power Supply: AC 110V/220V, 50/60Hz

- Diamension: 907*457 Or 1215*457 Or Customize

- Height Adjustment: Feet Cup

Technical Parameters:

| Power Supply | AC 110V/220V, 50/60Hz |

| Relay Brand | Schneider |

| Driver Brand | Meanwell |

| Pcb Dimension | L(50*50)-(450*330)mm |

| Pcb Flow Direction | L-R Or R-L (optional) |

| Air Pressure | 4-6kg/cm2 |

| Type | Automatic PCB Loader |

| Height Adjustment | Feet Cup |

| Board Thickness | Minimum 0.6mm |

| Board Collect Time | Each Approx 6 Seconds |

Applications:

Printed Circuit Board Handling Equipment is essential for the efficient and safe handling of PCBs in various manufacturing environments. These Automated PCB Handling Devices are designed to streamline the production process and ensure the smooth flow of printed circuit boards throughout the assembly line.

One of the key features of this PCB Handling Equipment is its communication capability through SMEMA (Surface Mount Equipment Manufacturers Association) standards. This allows for seamless integration with other equipment in the production line, ensuring a synchronized workflow.

Whether the PCB Flow Direction is from left to right or right to left, the equipment can be customized to meet the specific requirements of the manufacturing facility. This flexibility ensures compatibility with different production layouts and processes.

The Driver Brand used in this equipment is Meanwell, known for its reliability and high performance in industrial applications. This ensures stable operation and consistent handling of printed circuit boards throughout the manufacturing process.

With a minimum board thickness of 0.6mm, this Electronic Board Handling Equipment is suitable for a wide range of PCBs, accommodating varying thicknesses without compromising on performance.

Equipped with a Sick sensor, the PCB Handling Equipment ensures accurate detection and positioning of printed circuit boards, enhancing overall efficiency and quality in the production line.

These features make the Printed Circuit Board Handling Equipment ideal for a range of application occasions and scenarios. From small-scale electronics manufacturing to large-scale production facilities, this equipment can meet the demands of diverse industries. Whether handling single-sided or double-sided PCBs, this equipment offers precision and reliability in board handling processes.

Customization:

Product Customization Services for the Printed Circuit Board Handling Equipment:

Board Thickness: Minimum 0.6mm

Pcb Flow Direction: L-R Or R-L (optional)

Communication: SMEMA

Power Supply: AC 110V/220V, 50/60Hz

Driver Brand: Meanwell

Product Attributes: PCB Handling Machinery, ESD Safe PCB Handling Tools

Support and Services:

Our Product Technical Support team for PCB Handling Equipment is dedicated to providing timely assistance and expertise to ensure the smooth operation and maintenance of our equipment. Whether you require troubleshooting guidance, software updates, or detailed product information, our team is here to help.

In addition to technical support, we also offer a range of services to enhance the performance and lifespan of your PCB Handling Equipment. These services may include equipment calibration, preventive maintenance programs, training sessions, and spare parts management. Our goal is to maximize the efficiency and reliability of your equipment to support your business needs.

Packing and Shipping:

Product Packaging and Shipping:

Our PCB Handling Equipment product is carefully packaged to ensure safe delivery to our customers. Each unit is securely wrapped and placed in a sturdy cardboard box with ample cushioning materials to prevent any damage during transit.

For shipping, we partner with reliable courier services to guarantee timely and secure delivery to your doorstep. You will receive a tracking number once your order is dispatched, allowing you to monitor the shipping status of your product.

Contact Person: Sales Manager

Tel: +8613662694062

-

Unloader PCB Handling Equipment

-

Transfer 920mm PCB Handling Equipment

-

SMEMA Interface PCB Handling Equipment

-

SMT PCB Handling Equipment Multi Magazine Unloader For PCB Assembly

-

Multi PCB Magazine Unloader SMT Equipment Controlled by Omron PLC

-

High Accuracy Adjustable PCB Handling Equipment SMT PCB Loader 460C